Свяжитесь с нами по электронной почте :

info@labcompanion.cn-

-

Запрос звонка :

+86 18688888286

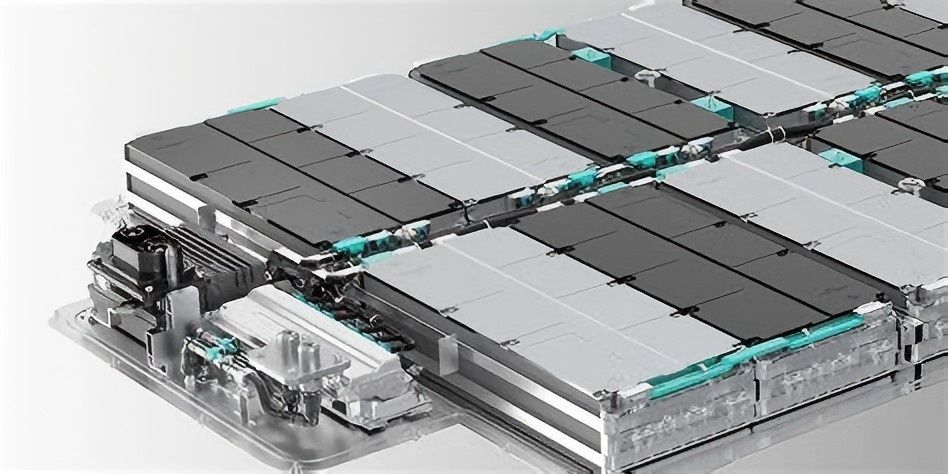

Аккумуляторные батареи объединяют несколько ячеек с BMS и терморегуляторами для стабильного питания. Основные области применения включают электромобили, накопители энергии, электронику, беспилотники и медицинские устройства. Примеры: Tesla 4680 и Blade Battery от BYD.

Испытание аккумуляторных батарей на воздействие температуры и влажности является критической оценкой их производительности и надежности в различных температурных и гигрометрических условиях. Для имитации реальных рабочих сред аккумуляторные батареи должны пройти комплексное тестирование в различных условиях, включая низкую температуру с низкой влажностью (LT/LH), низкую температуру с высокой влажностью (LT/HH) и высокую температуру с высокой влажностью (HT/HH).

В данной статье на основе реальных тематических исследований анализируются технические требования, которым должна соответствовать испытательная камера с постоянной температурой и влажностью для эффективного проведения этих оценок.

Основные технические требования к испытательным камерам:

Диапазон температур: Способен работать в экстремальных условиях (например, от -40°C до +85°C) с высокой стабильностью (±0,5°C).

Диапазон влажности: Регулируется от 10% до 98% относительной влажности, обеспечивая точность (±2% относительной влажности).

Скорость подъема: Управляемая скорость изменения температуры/влажности (например, ≥1°C/мин) для имитации быстрых изменений окружающей среды.

Однородность: Поддерживайте постоянное распределение температуры (±1°C) и влажности (±3% относительной влажности) в рабочем пространстве.

Регистрация данных: Мониторинг и регистрация параметров испытаний в режиме реального времени на предмет соответствия стандартам (например, ISO 16750, GB/T 31467).

Функции безопасности: Взрывозащищенная конструкция, обнаружение утечек и протоколы аварийного отключения для опасных ситуаций.

Условия испытаний аккумуляторной батареи на воздействие окружающей среды

1. Температурные испытания

Высокотемпературное хранение

Высокотемпературный цикл

Высокотемпературный разряд

Низкотемпературное хранение

Низкотемпературный запуск

Низкотемпературный цикл

Низкотемпературный разряд

2. Испытание на влажность

Испытание на циклическое воздействие влажного тепла: имитирует условия высокой температуры и влажности (например, 40°C / 95% относительной влажности) для оценки коррозионной стойкости и эффективности герметизации.

3. Испытание на воздействие соляного тумана

Испытание на коррозию в соляном тумане: имитирует прибрежную среду с высокой соленостью для проверки коррозионной стойкости аккумуляторной батареи.

4. Тестирование на водонепроницаемость

Испытание на проникновение воды: имитирует воздействие воды (например, погружение, дождь) для проверки водонепроницаемости (оценивается по степени защиты IP).

5. Тестирование на пыленепроницаемость

Испытание на проникновение пыли: имитирует среду с высоким содержанием пыли (например, пустыни) для проверки целостности уплотнения.

6. Испытание при низком давлении

Испытание на имитацию высоты: имитирует изменения атмосферного давления на разных высотах для оценки адаптивности аккумуляторной батареи.

Технические характеристики испытательной камеры постоянной температуры и влажности

(Соответствует требованиям заказчика)

Размеры камеры

Функциональные требования

1. Диапазон температур: от -60°C до +150°C

2.Скорость нагрева: ≥1°C/мин (средняя, при нагрузке: 1T, тепловая мощность 5кВт) от -40°C до +125°C

3. Скорость охлаждения: ≥1°C/мин (средняя, под нагрузкой: 1T, тепловая мощность 5 кВт) от +125°C до -40°C

4.Разрешение температуры: 0,01°C

5. Колебание температуры: ≤±0,2°C (без нагрузки)

6. Отклонение температуры: ≤±2°C

7. Равномерность температуры: ≤2°C (без нагрузки)

8. Непрерывная работа при низких температурах: 1000 часов при низких температурах без образования инея/обледенения (требуется система сухого воздуха)

9. Разрешение влажности: 0,1% относительной влажности

10. Колебание влажности: ≤±2,5% относительной влажности

11.Отклонение влажности:

≤+3% ОВ (при ОВ >75%)

≤±5% относительной влажности (при <75% относительной влажности)

12.Расширенные возможности эксплуатации:

Низкая температура и низкая влажность: 240 часов

Высокая температура и низкая влажность: 240 часов

Ключевые усовершенствования и научная строгость

1.Стандартные ссылки: добавлено неявное соответствие стандартам ISO, GB и IP для надежности.

2. Показатели точности: заданное разрешение, однородность и отклонение для удовлетворения инженерных требований.

3.Безопасность и надежность: особая защита от замерзания (система сухого воздуха) и возможность длительных испытаний.

4. Ясность и структура: организовано в логические разделы для удобства чтения при сохранении технической точности.

Чтобы соответствовать строгим требованиям испытаний аккумуляторных батарей на воздействие окружающей среды, наши передовые постоянные испытательные камеры температуры и влажности разработаны для обеспечения точности, надежности и соответствия мировым стандартам.

Почему стоит выбрать наши камеры для испытаний на воздействие окружающей среды?

✅ Широкий диапазон температур: от -70°C до +150°C для комплексных испытаний при высоких/низких температурах, включая термоудары.

✅ Быстрый переход температуры: скорость нагрева/охлаждения ≥1°C/мин под нагрузкой (1T, тепловая мощность 5 кВт).

✅ Высокая точность измерения влажности: относительная влажность 10–98 % с отклонением относительной влажности ±2,5 % и разрешением 0,1 % для точного цикла влажного тепла.

✅ Стабильная длительная работа:

✅ Однородность и точность:

✅ Большая емкость для тестирования: внутреннее рабочее пространство размером 3000×2000×2000 мм (Ш×Г×В) Климатическая испытательная камера для прогулок для полномасштабной оценки аккумуляторных батарей.

✅ Безопасность и долговечность: разработан для предотвращения теплового разгона, испытаний на соляной туман, водонепроницаемость (степень защиты IP) и пыленепроницаемость.